Product Overview

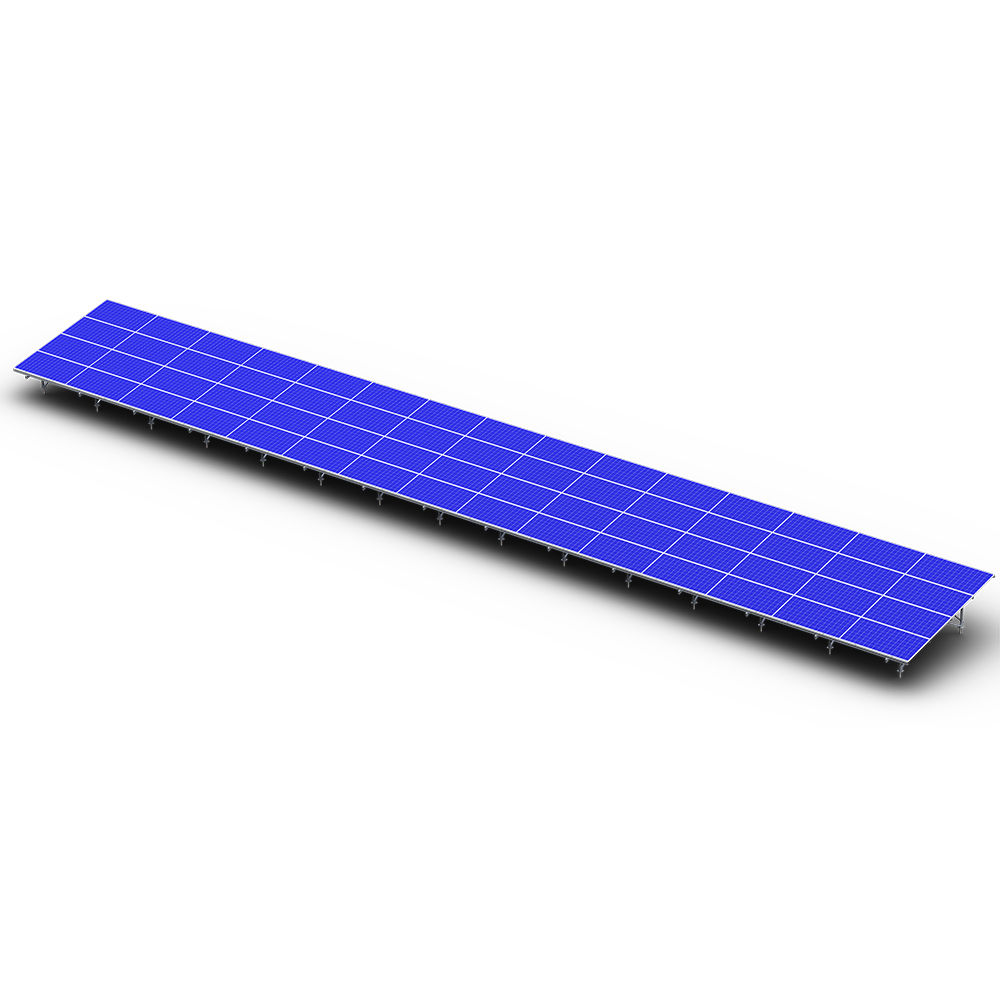

The ALUMSOLAR Aluminum Ground-Mounted Solar Racking System is a high-efficiency, reliable solution specifically designed for various ground-mounted PV power plants. It integrates high-strength aluminum alloy main structures with a patented ground screw foundation and is optimized for module portrait installation, perfectly combining the three major advantages of rapid installation, exceptional stability, and outstanding cost-effectiveness. Whether for large-scale ground-mounted power plants or projects on complex terrain, ALUMSOLAR provides a solid, long-term guarantee of over 25 years for your PV array.

Key Advantages

1. Rapid Installation, Cost Savings

Ground Screw Foundation: Requires no concrete pouring; screws are driven directly into the ground using specialized machinery, saving over 90% of foundation curing time. Unaffected by season or weather, significantly reducing labor and time costs.

Modular Design: Pre-assembled components and standardized connectors make on-site assembly like building blocks. The streamlined construction process is highly efficient and reduces dependency on skilled labor.

2. Rock-Solid Structural Stability

High-Strength Aluminum Alloy: Main rails and braces made from 6061-T6 or 6005-T5 high-strength aluminum alloy offer an excellent strength-to-weight ratio, easily handling extreme wind and snow loads.

Triangular Mechanical Design: The scientifically designed triangular support system efficiently transfers upper loads to the ground screws, ensuring the entire PV array remains stable as a rock even in harsh conditions like strong winds.

Deep Anchoring Force: Ground screws penetrate deep into the bearing soil layer, providing powerful pull-out and compression resistance, effectively preventing foundation settlement.

3. Superior Corrosion Resistance

Aluminum Alloy Body: Naturally corrosion-resistant, requiring no galvanizing, fundamentally eliminating rust issues.

Stainless Steel Fasteners: Critical connection points use A2-70 or A4-80 grade stainless steel bolts, resistant to acid and alkali corrosion, matching the system's lifespan.

Ground Screw Anti-Corrosion Coating: Ground screws feature thick-layer hot-dip galvanizing or Dacromet coating, ensuring long-term durability for the underground components.

4. Advantages of Portrait Installation

Perfect Compatibility: Optimized for today's mainstream large-format, high-power modules, ensuring worry-free compatibility.

Optimized Load Distribution: The long sides of the modules receive continuous, even support from the main rails, effectively reducing the risk of micro-cracks caused by deformation and enhancing long-term system reliability.

Neat Cable Management: Cables can be routed smoothly along the horizontal rails, resulting in a cleaner layout, reduced cable usage, less potential shading, and easier maintenance.

5. Excellent Terrain Adaptability

Minimal disturbance to the original ground, making it ideal for hilly areas, slopes, soft soil, or ecologically sensitive sites.

Easily adapts to various slopes by adjusting the exposed height of the screws and support legs, effortlessly maintaining a level mounting plane.

High strength Aluminum Ground Solar Mounting Structure

Parameter Category Detailed Specifications Main Material Aluminum Alloy 6061-T6 / 6005-T5 Surface Treatment Anodizing (Average Thickness ≥15μm) Foundation Type Steel Ground Screw (Hot-Dip Galvanized / Dacromet) Module Installation Portrait Wind Load Resistance ≥ 60 m/s (Reinforced design available based on project requirements) Snow Load Resistance ≥ 1.4 kN/m² (Reinforced design available based on project requirements) Design Service Life 25+ Years Compatible Modules Compatible with various crystalline silicon modules, supports widths up to 1300mm+ Corrosion Resistance Class C4 or higher (Customized based on environment) Standard Certifications ISO 9001, ISO 14001, TÜV, UL